Click me to see more Original picture

Click me to see more Original picture

Click me to see more Original picture

Click me to see more Original picture

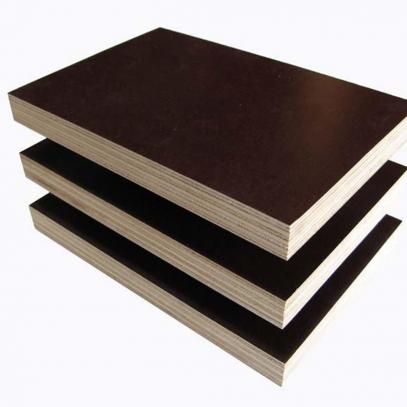

WBP Glue concrete shuttering plywood

In plywood business, a lot of people sell / buy WBP plywood / film faced plywood . But only a few people know the real meaning of the word “WBP” . Thus, what is the real meaning of WBP ?

WBP stands for “Weather and Boil Proof”, the WBP performance is inspected through “Water Boiling Proof” test. The requirement is listed under European plywood standard EN 314-2 Plywood – Bond quality – Requirements Bond Class 3: Exterior conditions. If you use WBP glue for the plywood / film faced plywood, the panel will can be exposed to weather, water and moisture for a long period (some maybe permanently without delamination . Like the word of “MR“, WBP is not the name of a specific glue . WBP is only a kind of bonding property / feature of glue. If a glue has WBP property, the glue will can be called WBP glue.

As a simple method of test for WBP plywood, you can put the plywood samples into the boiling water. If the samples have not delaminated in boiling water for a long period, then we will can say the plywood samples have WBP property and conclude that the samples are WBP plywood samples.

Generally speaking, WBP(ordinary melamine) plywood can be in boiling water for 4-8 hours without delamination and WBP(better melamine) plywood can be in boiling water for over 10 hours or even 20 hours without delamination . WBP (phenolic) plywood can be in boiling water for 24-72 hours without delamination . The best WBP(phenolic) glue can be regarded as permanent adhesives .But the water boiled proof period of plywood is depended on not only the quality of WBP glue, but also the craftsmanship of production.

Usually, people like use WBP glue for exterior plywood, such as Marine plywood, film faced plywood (formwork plywood), structural plywood, plywood for signs and so on. But in practice, WBP glue is used for interior plywood as well, such as furniture plywood, cabinet plywood, plywood underlayment and so on, which are also required by customers to have Weather-boiled-proof(WBP) property.

In plywood industry, WBP stands for Weather and Boil Proof, the classification of glue used to make the most durable plywood especially in moisture and water condition. WBP glues are made with melamine or phenolic resin. To be considered exterior grade or marine grade, plywood must be made with WBP glue.

WBP plywood made with regular melamine rather than phenolic resin can maintain lamination in boiling water for between four and eight hours. High quality melamine plywood can withstand boiling water for 10 to 20 hours. WBP plywood using ordinary phenolic resin glue can handle boiling water for one to three days. It should be noted that the length of time plywood can withstand boiling water without delaminating is not only dependent on the glue – it also depends on the production process and raw materials of the plywood used.

PRODUCT DETAILS

| Product Name | WBP Plywood | |

| Core: | Poplar, Hardwood, Combi, Birch, eucalyptus, as your requirement. | |

| Grade: | BB/BB, BB/CC, CC/CC, CC/DD, etc. | |

| Glue: | WBP | |

| Size(mm) | 1220*2440mm, 1250*2500mm | |

| Thickness(mm) | 2.0-25.0mm | 1/8inch(2.7-3.6mm) |

| 1/4inch(6-6.5mm) | ||

| 1/2inch(12-12.7mm) | ||

| 5/8inch(15-16mm) | ||

| 3/4inch(18-19mm) | ||

| Moisture | 16% | |

| Thickness tolerance | Less than 6mm | +/-0.2mm to 0.3mm |

| 6-30mm | +/-0.4mm to 0.5mm | |

| Packing | Interior packing:0.2mm plastic;

Outside packing: bottom is pallets, covered with plastic film, around is carton or plywood, strengthen by steel or iron 3*6 |

|

| Quantity | 20GP | 8pallets/21M3 |

| 40GP | 16pallets/42M3 | |

| 40HQ | 18pallets/53M3 | |

| Usage | Usage adequate for making furniture or construction, package or industry, | |

| Minimum Order | 1*20GP | |

| Payment | TT or L/C at sight | |

| Delivery Time | Within 15 days received deposit or original L/C at sight | |

Features:

1 wear-resistant, anti-cracking, anti-acid and alkaline-resistant

2 no color cotamination between the concrete and shuttering board

3 can be cut into small size for reusing.

Judge which kind of plywood you need according to your actual situation. All kinds of plywood are produced by booster wood industry with high quality. You are welcome to order.

Product Abstract:WBP stands for “Weather and Boil Proof”, the WBP performance is inspected through “Water Boiling Proof” test. The requirement is listed under European plywood standard EN 314-2 Plywood – Bond quality – Requirements Bond Class 3: Exterior conditions. If you use WBP glue for the plywood / film faced plywood, the panel will can be exposed to weather, water and moisture for a long period (some maybe permanently without delamination .

Get a Free Quote